Written by Lee Murphy (@LeeMurphyCRF),

Genetics Manager, Edinburgh Clinical Research Facility

September 2019

Freezers need to work hard to keep important samples and reagents at a safe temperature. Ultra Low Temperature (ULT) freezers are also one of the most energy hungry items in the laboratory, using up to £1,000 of energy each year. By looking after our freezers and following these five tips we can ensure sample integrity and have a positive impact on the environment

1. Give them space

To work efficiently a freezer needs to have a constant flow of air. Generally cool air is pulled through filters at the front and bottom of the freezer to the back where heat transfer occurs at the condensers, the warm air then rises and re-enters the room. To help the air flow freezers should not be pushed up too close to the wall, or to each other, so try to leave at least a 30cm gap at the back and sides. Most importantly, nothing should be stored on top of the freezer, a mistake that happens in many labs.

Running a ULT freezer at -70oC, rather than -80oC, will result in an energy reduction of about 30% and will help prolong the life of the compressor. Air conditioning can also help heat exchange and limit how hard the freezer compressor is working but this comes at an environmental cost. Before turning on the air conditioning, consider if a lower tech solution is available.

Well-spaced freezers in a well-ventilated room

2. Keep them maintained

Your freezers work hard so you need to give them Tender Loving Care. They should be on a maintenance contract with maintenance visits scheduled every 6 months. In addition the following checks should be carried out regularly:

- Check the filters and clean them each month to ensure air is flowing smoothly. Plastic film wrap from tip boxes is a particular menace but a general build-up of dust can be just as harmful.

- Wipe the door seals regularly and replace if damaged. This limits the build-up of condensation and therefore of ice build-up on the doorframe.

- Check the door handle and hinges. A build-up of ice can cause these to be out of alignment, and once a gap occurs in the door further ice will develop quickly.

- Don’t force the freezer door open, use the auto-vent button, when available, to release the vacuum.

- Defrost regularly. This is a rubbish job but unavoidable. An iced up freezer will have less space to store samples and the compressor will have to work much harder to maintain the temperature and so will be more likely to fail. Defrost once you see a build-up of ice, this will probably be annually but may be more regular for a freezer that is used more intensely. If you are seeing a regular build-up of ice inside the freezer this could indicate a damaged seal, a poorly fitted door or the freezer door left open too long.

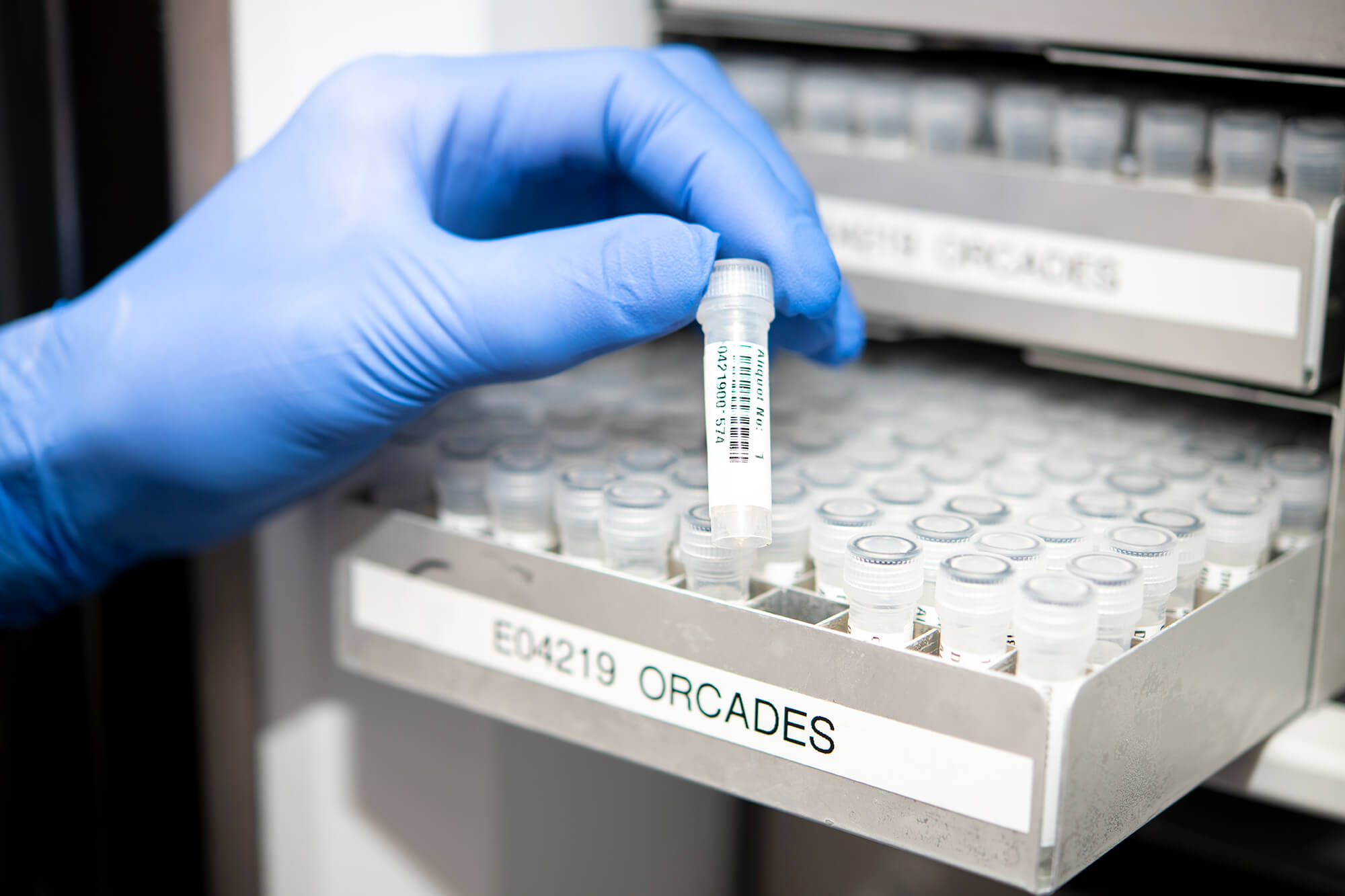

3. Use racking

A well thought out racking system will make the most efficient use of precious freezer space and will allow easy access to the samples. Metal racks act as a cold sink, stabilising the temperature during door openings and slowing the heating process if a freezer does fail. Stainless steel racks retain the cold longer than cheaper aluminium racking. The cost of racking can be high and so should be budgeted when purchasing a new freezer, with racking costing roughly the same as a new ULT.

Good racking is expensive but worth it

4. Use a sample management system

A good sample inventory system means you will know where samples are so will spend less time with your head in the freezer. Leaving the door open means greater fluctuation in temperature inside the freezer and less efficient running. Use printed sample labels and barcode labelling so that samples can identified quickly. The other benefit of a sample management system is that you will have a ready track of samples stored, so you know when a freezer is filling up and when you need to consider buying a new one. Most importantly, it also provides a list of samples that you are no longer using and you may be able to dispose to free space.

5. Have a back-up plan

In case the worse does happen you need an effective back-up plan to kick in to action.

All freezers with anything important in should be on an alarm system that has the ability to call out first responders 24 hours a day. The coldest area in a freezer is at the bottom and back so if you have particularly vital samples place them there. The warmest area in the freezer is at the top and front so the alarm probe should be placed here to allow maximum notice of any issue. Consider carefully what temperature the alarm should be triggered. If it is too warm then it does not leave you much time after a call to rectify. If it is too cold then you may get false alarms just by entering the freezer.

If somebody is called out, then you need a plan of what to then do. In most cases this will involve moving samples to other freezers so you will need to ensure that you have an empty freezer or that there is space within your current freezers.

To ensure sample integrity it is advantageous to ensure samples are separated in to separate aliquots and stored in different freezers. In case one freezer breaks down another aliquot will be safely stored.

Once you have a plan you need to check that it works. For example does the freezer alarm really call out? (I have heard of an occasion where the freezer alarm was plugged in to a phone line that did not allow external phone calls). Does the call-out list have all the relevant people, do their phones work, and are they reachable?

Lee Murphy is the Genetics Manager at the Edinburgh Clinical Research Facility where he leads a team processing and analysing clinical samples.

Lab Blog: https://edinburghcrf.wordpress.com/

Tweets: @LeeMurphyCRF